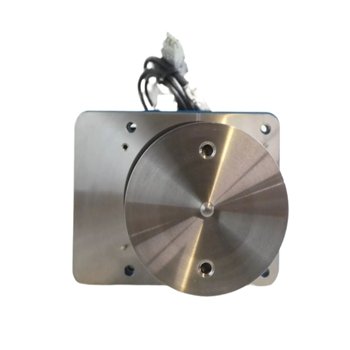

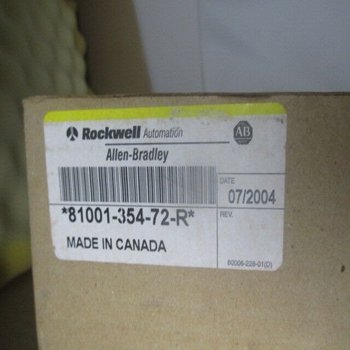

A-B MOX12-P3509 Industrial Control Module for Advanced Process Automation

Introducing the A-B MOX12-P3509, a premier addition to the A-B automation products lineup designed to enhance operational efficiency and reliability across various applications. This model is engineered with cutting-edge technology, making it a vital component for businesses aiming to optimize their automation processes. The MOX12-P3509 stands out with its robust feature set, versatile usage scenarios, and competitive advantages over other models within the A-B family.

Key Technical Features

The A-B MOX12-P3509 boasts a range of advanced technical features that cater to the demands of modern automation systems. It is equipped with high-performance processing capabilities, ensuring rapid data handling and seamless integration with other A-B automation products. The model supports multiple communication protocols, facilitating easy connectivity with various devices and systems, which is essential for creating a cohesive automation environment.

One of the standout features of the MOX12-P3509 is its exceptional durability. Designed to withstand harsh industrial conditions, this model operates reliably even in extreme temperatures and high-vibration settings. This resilience makes it an ideal choice for manufacturing plants, assembly lines, and other demanding environments.

Additionally, the A-B MOX12-P3509 includes an intuitive user interface that simplifies configuration and monitoring. This user-friendly design allows operators to quickly set up and modify parameters with minimal training, thereby reducing downtime and increasing productivity. The model's modular architecture also means that it can be easily upgraded or expanded, ensuring that businesses can adapt their systems to meet evolving needs.

Usage Scenarios

The versatility of the A-B MOX12-P3509 makes it suitable for a wide range of applications. In manufacturing, it can be used to control assembly lines, manage robotic arms, and monitor production processes, ensuring that operations run smoothly and efficiently. The model's ability to communicate with various sensors and actuators allows for real-time data acquisition and analysis, enabling timely decision-making and process adjustments.

In the oil and gas industry, the MOX12-P3509 can be employed for remote monitoring and control of equipment, enhancing safety and operational effectiveness. Its robust design and reliable performance in hazardous environments make it a preferred choice for applications where equipment failure could result in significant downtime or safety risks.

Additionally, the A-B MOX12-P3509 is well-suited for water and wastewater treatment facilities. Its ability to integrate with SCADA systems allows for efficient monitoring of water quality and flow rates, ensuring compliance with environmental regulations while optimizing resource usage.

Comparison with Other Models

When comparing the A-B MOX12-P3509 with other models in the A-B product range, several key differences emerge. For instance, while the A-B 1756-CN2R offers similar communication capabilities, it lacks the MOX12-P3509's user-friendly interface and modular design, which can hinder flexibility in dynamic environments.

Similarly, the A-B 511367-01 is known for its ruggedness; however, it does not match the processing speed and data handling capabilities of the MOX12-P3509. In contrast to the A-B 2711-K5A1, which is primarily focused on visualization and control, the MOX12-P3509 excels in processing and data integration, making it a more comprehensive solution for automation needs.

For businesses seeking a comparable option, the A-B 1756-OF4 offers a specific focus on output functionality but lacks the overall versatility and integrated communication protocols found in the MOX12-P3509. The A-B 1771-OFE2 and A-B 2791-BM01-S are also notable models; however, their limitations in processing power and user interface design may not meet the growing demands of modern automation systems.

Related Models

For those exploring additional options within the A-B automation products family, consider these related models:

1. A-B 1755-A6

2. A-B 20-750-2262C-2R

3. A-B 2711-T10C8

4. A-B 1771-IBD

5. A-B 1394-AM75 B

6. A-B 1756-PA72

7. A-B 1756-IR6I

8. A-B 1783-MS10T

9. A-B 80190-378-51/12

10. A-B 440N-C02068

Each of these models offers unique features and capabilities tailored to specific automation tasks while sharing the reliable performance and quality associated with the A-B brand.

Conclusion

The A-B MOX12-P3509 is a versatile, high-performance solution designed to meet the demands of modern automation across various industries. Its robust technical features, user-friendly interface, and adaptability make it an ideal choice for businesses looking to enhance their operational efficiency. With its proven track record and competitive advantages over other models, the MOX12-P3509 is an essential component for any organization invested in A-B automation products. Whether in manufacturing, oil and gas, or water treatment, this model promises to deliver reliability and performance that exceeds expectations. Embrace the future of automation with the A-B MOX12-P3509, where innovation meets excellence.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The A-B MOX12-P3509 boasts a range of advanced technical features that cater to the demands of modern automation systems. It is equipped with high-performance processing capabilities, ensuring rapid data handling and seamless integration with other A-B automation products. The model supports multiple communication protocols, facilitating easy connectivity with various devices and systems, which is essential for creating a cohesive automation environment.

One of the standout features of the MOX12-P3509 is its exceptional durability. Designed to withstand harsh industrial conditions, this model operates reliably even in extreme temperatures and high-vibration settings. This resilience makes it an ideal choice for manufacturing plants, assembly lines, and other demanding environments.

Additionally, the A-B MOX12-P3509 includes an intuitive user interface that simplifies configuration and monitoring. This user-friendly design allows operators to quickly set up and modify parameters with minimal training, thereby reducing downtime and increasing productivity. The model's modular architecture also means that it can be easily upgraded or expanded, ensuring that businesses can adapt their systems to meet evolving needs.

Usage Scenarios

The versatility of the A-B MOX12-P3509 makes it suitable for a wide range of applications. In manufacturing, it can be used to control assembly lines, manage robotic arms, and monitor production processes, ensuring that operations run smoothly and efficiently. The model's ability to communicate with various sensors and actuators allows for real-time data acquisition and analysis, enabling timely decision-making and process adjustments.

In the oil and gas industry, the MOX12-P3509 can be employed for remote monitoring and control of equipment, enhancing safety and operational effectiveness. Its robust design and reliable performance in hazardous environments make it a preferred choice for applications where equipment failure could result in significant downtime or safety risks.

Additionally, the A-B MOX12-P3509 is well-suited for water and wastewater treatment facilities. Its ability to integrate with SCADA systems allows for efficient monitoring of water quality and flow rates, ensuring compliance with environmental regulations while optimizing resource usage.

Comparison with Other Models

When comparing the A-B MOX12-P3509 with other models in the A-B product range, several key differences emerge. For instance, while the A-B 1756-CN2R offers similar communication capabilities, it lacks the MOX12-P3509's user-friendly interface and modular design, which can hinder flexibility in dynamic environments.

Similarly, the A-B 511367-01 is known for its ruggedness; however, it does not match the processing speed and data handling capabilities of the MOX12-P3509. In contrast to the A-B 2711-K5A1, which is primarily focused on visualization and control, the MOX12-P3509 excels in processing and data integration, making it a more comprehensive solution for automation needs.

For businesses seeking a comparable option, the A-B 1756-OF4 offers a specific focus on output functionality but lacks the overall versatility and integrated communication protocols found in the MOX12-P3509. The A-B 1771-OFE2 and A-B 2791-BM01-S are also notable models; however, their limitations in processing power and user interface design may not meet the growing demands of modern automation systems.

Related Models

For those exploring additional options within the A-B automation products family, consider these related models:

1. A-B 1755-A6

2. A-B 20-750-2262C-2R

3. A-B 2711-T10C8

4. A-B 1771-IBD

5. A-B 1394-AM75 B

6. A-B 1756-PA72

7. A-B 1756-IR6I

8. A-B 1783-MS10T

9. A-B 80190-378-51/12

10. A-B 440N-C02068

Each of these models offers unique features and capabilities tailored to specific automation tasks while sharing the reliable performance and quality associated with the A-B brand.

Conclusion

The A-B MOX12-P3509 is a versatile, high-performance solution designed to meet the demands of modern automation across various industries. Its robust technical features, user-friendly interface, and adaptability make it an ideal choice for businesses looking to enhance their operational efficiency. With its proven track record and competitive advantages over other models, the MOX12-P3509 is an essential component for any organization invested in A-B automation products. Whether in manufacturing, oil and gas, or water treatment, this model promises to deliver reliability and performance that exceeds expectations. Embrace the future of automation with the A-B MOX12-P3509, where innovation meets excellence.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.