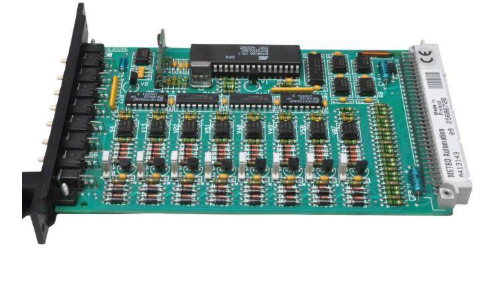

METSO A413144 plc control module

METSO A413144 plc control module

Turbine Generator Machine Protection

Monitoring of Turbine-Generators with

measurements of:– thrust position with eddy probes– shaft movement with eddy probes– case expansion with eddy probes or LVDT´s– differential expansion with eddy probes, single or

swap-over– shaft eccentricity with eddy probes– absolute vibration with accelerometers or velomitors

Designed according to API670 standard– Protective monitoring by the I/O cards– Cards operate even if connection into PCS is lost– Redundant power supply unit– Redundancy supported for protection only solution

Technical Parameters (Technical Data)

| Parameter | Specification |

| Component Type | Pneumatic Relay / Amplifier Module |

| Supply Pressure Range | 1.4 – 8.0 bar (20 – 115 psi) |

| Air Delivery Capacity | Optimized for fast stroking (approx. 8–18 $Nm^3/h$ depending on supply) |

| Steady-state Air Consumption | Very Low (< 0.1 $Nm^3/h$ at 4 bar) |

| Operating Medium | Filtered, non-lubricated air or sweet natural gas |

| Filtration Requirement | < 40 $\mu m$ (5 $\mu m$ recommended for longevity) |

| Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Housing Material | High-grade Aluminum with corrosion-resistant coating |

Valmet DNA Turbine Protection I/O

Machine protection

AIF4E

Eddy current measurement for shaft

position or vibration measurement- 4 input channels- each channel configurable for

both static and dynamic values,- 2 calculated values per

channel supported- 100 ms update rate (API670)- raw signal sample buffers for

diagnostic application- 4 output channels 4 – 20 mA ,

any value to any output

Machine protection

AIF4V

Absolute vibration

measurement using

accelerometers or velomitors

Machine protection

AIT4L

Casing absolute expansion and

valve position- 4 input channels- each channel configurable for

2 calculated values per

channel, rms or peak, vibration

acceleration or velocity- 100 ms update rate (API670)- raw signal sample buffers for

diagnostic application- 4 output channels 4 – 20 mA ,

any value to any output

4 input channels

Isolation- Field to system 1500 VAC- Between channels 1500 VAC- 4 LVDT/RVDT input channels- 5 and 6 wire LVDT/RVDT support- all electronics in card, only LVDT

sensor

out in the field- input update interval 1 ms- settable measurement

Controller and power supply

functions

ACN MR, 2x IPSP- redundancy in HW and SW- redundant power supply- self diagnostic- communication to 3rd party (Modbus TCP, Profibus, etc)-

integrated part of Valmet DNA system network- alarms and events- configuration of I/O cards with EAS SW-card parameter download when card is changes(hot swap)- optional diagnostic