LEYBELOD PR25 Penning meter

The Leybold PENNINGVAC PR 25 is a high-performance passive cold cathode ionization gauge (also known as a Penning gauge).

It is a classic industry standard for high-vacuum measurements where robustness and durability are required.

1. Product Description

The PR 25 belongs to the Penning style of vacuum gauges, which measure pressure by ionizing gas molecules through a high-voltage discharge in a magnetic field.

Unlike “active” gauges that have integrated electronics, the PR 25 is a passive sensor, meaning it must be connected via cable to an external controller (like the COMBITRON or DISPLAY series) which provides the power and processes the measurement signal.

Measurement Principle: Cold cathode ionization.

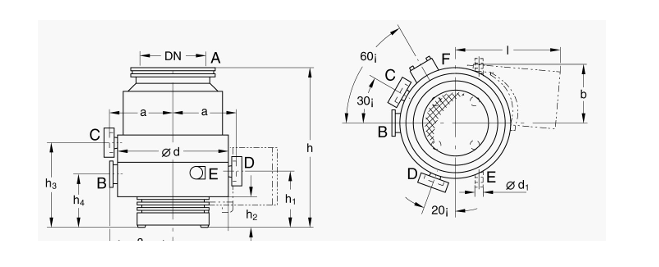

Design: Rugged stainless steel construction with a standardized KF25 flange.

2. Technical Parameters

| Parameter | Specification |

| Measurement Range | $1 \times 10^{-9}$ mbar to $1 \times 10^{-2}$ mbar |

| Connection Flange | DN 25 ISO-KF |

| Operating Temperature | Up to +80°C (Standard) / Bakeable versions available |

| Supply Voltage | Provided by external controller (approx. 3 kV during operation) |

| Materials in Vacuum | Stainless steel, Alumium oxide ceramics, FPM (Viton) |

| Weight | Approx. 0.4 kg |

| Part Number (Common) | 15752 |

3. Product Advantages & Features

Extreme Durability: Since there is no hot filament to burn out (unlike Hot Cathode gauges), the PR 25 is resistant to sudden air inrushes and high-pressure bursts.

Easy Maintenance: The gauge is designed for periodic cleaning. The internal anode ring and cathode plates can be removed and cleaned or replaced, extending the life of the sensor.

Compact Design: The small footprint and KF25 flange allow for easy integration into existing vacuum lines.

High Sensitivity: Capable of measuring deep into the high-vacuum range ($10^{-9}$ mbar) with high repeatability.

PR25

4. Application Cases

High Vacuum Systems: Monitoring vacuum levels in turbomolecular or diffusion pump systems.

Industrial Coating: Used in sputtering and evaporation systems where robustness against process gases is critical.

Particle Accelerators: Providing reliable high-vacuum monitoring in beamlines.

Analytical Instruments: Serving as a safety interlock or measurement gauge for mass spectrometers and electron microscopes.

PR25

5. Related & Other Models in the Series

The PR 25 is part of a family of passive sensors differentiated primarily by their flange type and bakeability:

PR 26: Equipped with a DN 40 ISO-KF flange.

PR 27: Equipped with a DN 40 CF (ConFlat) flange for ultra-high vacuum (UHV) compatibility.

PR 28: A specialized bakeable version for UHV applications, typically featuring a CF flange.

PTR 225: The “Active” version of this gauge (includes integrated electronics and does not require a separate controller unit).

Compatible Controllers:

COMBITRON CM330 / CM350