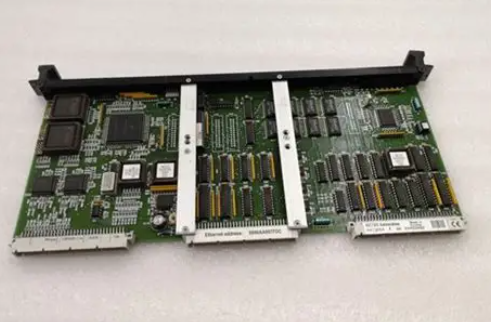

METSO A413345 Power Supply / Filter / Distribution Board

the METSO A413345 is a specialized module belonging to the Valmet / Metso DNA (formerly Damatic) automation family.

This specific part is generally identified as a Power Supply and Distribution Module or a Power Filter Unit used to provide stable, filtered energy to the processing boards within the system rack.

1. Product Description

The METSO A413345 is a high-reliability power management card. In a Distributed Control System (DCS), sensitive processor boards (like the A413665) require clean, surge-protected power to prevent data corruption or hardware failure.

The A413345 filters the incoming cabinet power (typically 24V DC) and distributes it across the backplane to various I/O and control modules.

Manufacturer: Valmet / Metso Automation

Component Type: Power Supply / Filter / Distribution Board

System Compatibility: Metso DNA / Damatic XDi

Installation: Slot-mounted in a standard Metso system sub-rack.

2. Technical Data Sheet (Specifications)

| Parameter | Specification |

| Model Number | A413345 |

| Function | Power Distribution & Filtering |

| Input Voltage | 24V DC (Standard Industrial Range) |

| Output Voltage | Regulated 24V DC / 5V DC (Internal Bus) |

| Protective Features | Over-voltage, Over-current, and Short-circuit protection |

| Indicators | Front-panel LEDs for Power OK and Status |

| Weight | Approx. 1.2 kg |

| Cooling | Passive convection cooling |

| MTBF | High (designed for 10+ years of continuous operation) |

3. Related Models

The A413345 is essential for the operation of its “neighbor” cards in the rack:

A413665 / A413654: Processor modules that receive power from this unit.

A413110 (TIU6): Interface unit used for field wiring.

D100532: Bus connection module.

A413340 / A413342: Similar power modules with different current ratings or redundancy features.

4. Application Cases

Refining & Chemicals: Ensuring the DCS remains powered during minor voltage fluctuations to prevent hazardous unplanned shutdowns.

Pulp & Paper: Providing stable power to the logic controllers governing massive paper machines where electrical noise from large motors is prevalent.

Power Plants: Used in turbine control systems where power reliability is a regulatory requirement.

Mining: Protecting control electronics from the “dirty” power often found in remote sites using generator sets or long-distance power lines.

5. Product Features and Advantages

Electrical Noise Suppression: Features advanced filtering circuitry to remove electromagnetic interference (EMI) that can disrupt digital signals.

Hot-Swap Support: In many rack configurations, the power system is designed to allow module replacement without interrupting the process (Redundancy).

Industrial Grade: Built to withstand high-ambient temperatures in sealed control cabinets.

Diagnostic Feedback: The integrated LEDs provide instant visual confirmation of power health, reducing troubleshooting time.

Galvanic Isolation: Helps isolate the sensitive control logic from external electrical faults.

A413345

6. Other Models in the Same Series

The Metso A413xxx series is divided by functional blocks:

A4131xx: Terminal and Field Interface (e.g., A413110).

A4132xx: Signal Processing and Channel Boards (e.g., A413222).

A4133xx: Power Management and Distribution (e.g., A413300. A413345).

A4136xx: Central Processing and Active Control (e.g., A413665).