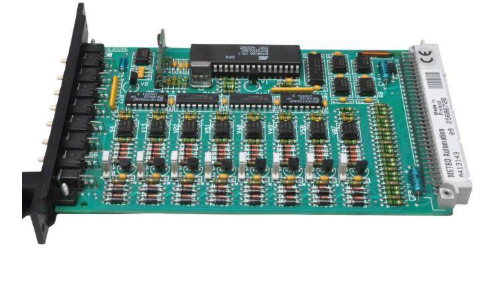

METSO A413110 PCB Card / Interface Board

Here is the comprehensive English product information for the METSO A413110

1. Product Description

The METSO A413110 (often identified as the TIU6 or TIU 6 card) is a high-performance PC Board PLC / Add-On Board designed for industrial automation and process control.

It is part of the legacy Valmet/Metso automation series, primarily used for interfacing and managing control logic within distributed control systems (DCS).

Type: PCB Card / Interface Board

Designation: TIU6 (Terminal Interface Unit)

Manufacturer: Metso Automation (now part of Valmet)

Mounting: Slot-based mounting in standard PLC racks or sub-racks.

2. Technical Data Sheet (Specifications)

| Parameter | Specification |

| Model Number | A413110 |

| Part Number | A413110 / TIU6 |

| Weight | Approximately 1.7 kg (0.02 lbs for the bare board) |

| Input Voltage | System-dependent (standard PLC levels) |

| Indicators | Integrated LED status indicators (Power, Run, Fault) |

| Country of Origin | Finland / USA |

| Interface | Terminal Interface Unit (TIU) communication protocols |

| Cooling | Natural convection / Rack airflow |

3. Related Models

The A413110 is often used in conjunction with other components of the Metso/Valmet DNA system or the Neles ValvGuard series. Related hardware includes:

A413100: Similar interface board series.

VG9000 Series: Intelligent safety solenoids often controlled via Metso automation boards.

Metso AC800M: Common PLC platform where these boards may be integrated.

I/O Modules: Various digital and analog input/output cards compatible with the TIU6 rack.

4. Application Cases

The METSO A413110 is typically found in heavy industrial environments requiring high reliability:

Mining & Aggregates: Used in the automation of Lokotrack® mobile crushers and Nordberg® stationary plants to manage motor controls and safety interlocks.

Pulp & Paper: Integration into Valmet DNA systems for paper machine control.

Oil & Gas: Controlling ESD (Emergency Shutdown) and ESV (Emergency Venting) valves via partial stroke testing systems.

Power Plants: Managing auxiliary control loops and data acquisition from field sensors.

5. Features and Advantages

Reliability: Built for 24/7 operation in harsh industrial environments (dust, vibration, and temperature fluctuations).

Real-time Diagnostics: Features LED indicators on the front panel for immediate troubleshooting of power and communication status.

Modular Design: The “Slot Mounting” design allows for quick replacement (Hot-swapping in supported frames), minimizing downtime during maintenance.

Integration: Seamlessly communicates with HART and Foundation Fieldbus protocols when used in Valmet automation architectures.

Longevity: Even as a discontinued manufacturer item, it is highly sought after for its durable build quality in “Life Cycle Services.”

A413110

6. Other Models in the Same Series

In the Valmet/Metso automation catalog, you will often find:

A413xxx Series: Boards ranging from power supply modules to communication processors.

TIU Series: TIU1. TIU2. and TIU6 boards, which differ based on the number of channels or the specific protocol translation they handle.

Neles ValvGuard VG9000: Often the field-side “partner” to these control cards.