Yaskawa U1000 Matrix frequency converter

Yaskawa U1000 Matrix frequency converter

Next-generation motor driver.

Hope to solve the problems existing in the frequency converter!

To fulfill this long-cherished wish, Yaskawa Electric has developed products applying matrix frequency converter technology. In the continuous pursuit of evolution, the U1000 was born. Yaskawa Preferred Motor Drivers provide “answers” to the problems existing for customers.

Features

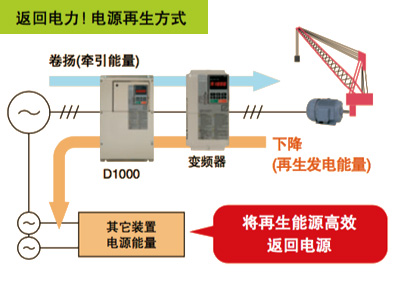

Renewable energy

When a motor rotates, it consumes energy and generates electricity at the same time.

Energy conservation can be achieved by making full use of this energy.

What is renewable energy?

“Visualized electricity saving

By using analog output and communication networks, etc., various data can be monitored through simple operations. Energy conservation is clear at a glance, and you can truly experience the effect of electricity saving.

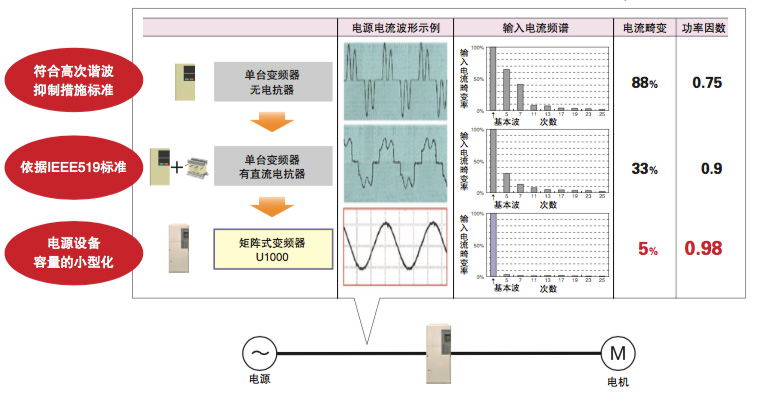

High power factor, no high-order harmonics of the power supply!

The input current does not require special equipment and is almost the same as the sine wave of commercial power supplies, enabling the realization of high-order harmonics without power supply. It is easy to achieve the miniaturization of power supply equipment capacity and meet the standards for measures to suppress high-order harmonics (K5=0).

What are high-order harmonics

When a frequency converter is performing power conversion, it may generate high-order harmonics due to the distortion of the input current. Sometimes, this can lead to overheating and damage of power supply equipment, or cause malfunctions and noise in precision equipment, which may endanger other electrical equipment.

The miniaturization of power supply equipment capacity

The power factor is high, so a smaller capacity of the power supply equipment is sufficient. Moreover, the size of the wires and the capacity of the generators can both be miniaturized.

Integrated design, compact structure!

When connecting matrix frequency converters, there is no need for the previously necessary high-order harmonic response products (AC reactors for input, reactors for high-order harmonic filters and capacitors), which helps to save wiring, space and reduce energy loss.