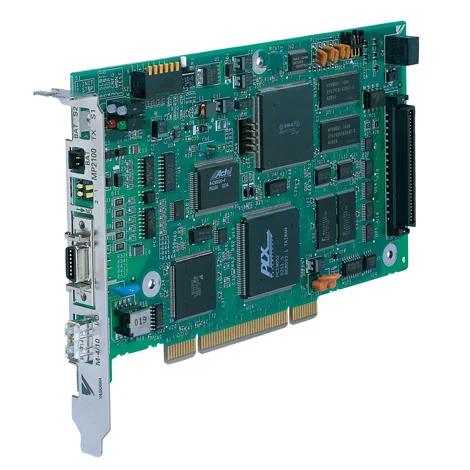

Yaskawa MP2300/MP2310/ Integrated controller.

MP2300/MP2310/

MP2300S

An integrated controller with built-in power supply, CPU, communication and servo control.

From simple positioning and interpolation to advanced multi-axis control, devices that pursue cost performance.

Features

Corresponding to open network

Just install the selected module in the slot. It can not only correspond to open networks but also expand I/O.

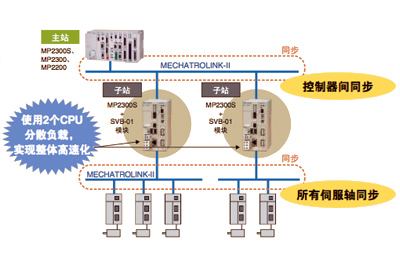

Synchronous processing of sequential and motion control

Due to the new high-speed design, not only has the processing speed of the CPU been enhanced, but also the complete synchronous processing of sequential and motion control has been achieved.

The speed of the sports network is 10Mbps

By connecting the servo driver to a high-speed motion network, it is possible to change the gain online during mechanical action. Switch speed, torque and position control, and freely control the mechanical movement.

Simple Settings

Since it can automatically identify the optional modules and servo drives connected to the MP2300, the previously necessary definition inputs are now no longer required.

Equipped with a new ladder diagram editor and application conversion function

Programming in the Windows environment not only enhances operability but also features a conversion function from the motion controller MP930 to MP2300. And it has convenient functions from design to maintenance, making it a controller that is not merely confined to the simplicity of use.